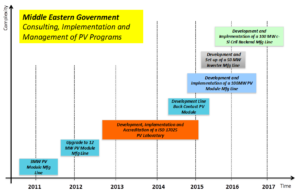

Consulting Projects

Middle East Government Consulting

- Consulting and Implementation of Photo Voltaic Projects for Saudi Arabia.

- Initially Contracted for a 3 Month Period in early 2011 mainly to source critical material for a newly installed, small PV Module Manufacturing Line.

- The Contract was extended for a 10 Month Period as they where seeking expertise to operate the PV Module Line with local Saudi people and transfer the required knowledge and technology to Saudi Arabia.

- The initial task included to assigning a local team, establishing a strong link to the Equipment Vendor and RAW Material Sources, training the local Team, setting up manufacturing processes and infrastructure plus balancing the manufacturing line for optimized output.

- Since the initial 10 Month Contract, it has been extended uninterrupted and is still ongoing. From the initial 3 MW PV Module Manufacturing Line, we have advised, consulted and managed for the Saudi Government on multiple Projects of increasing complexity.

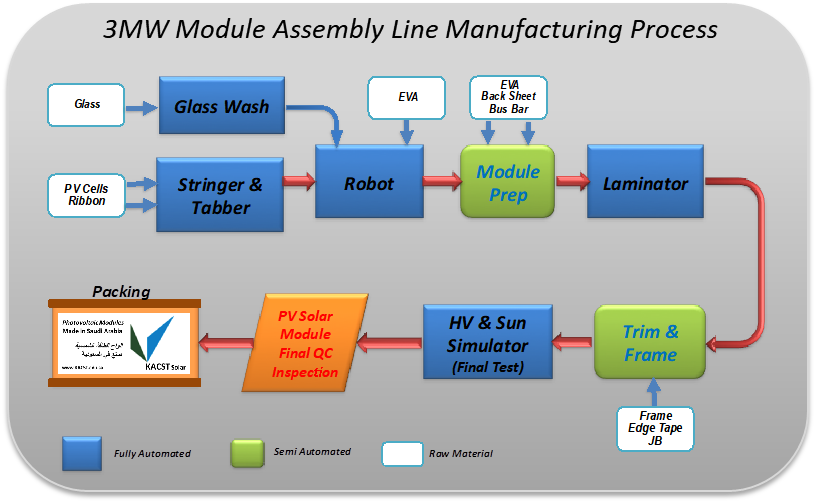

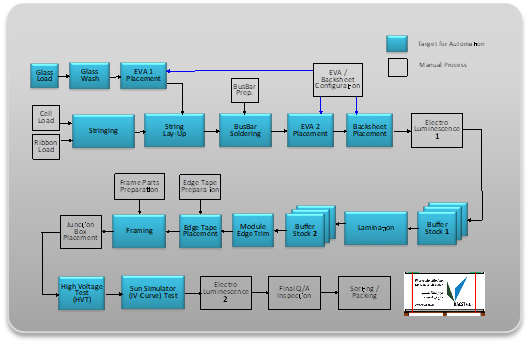

3MW PV Module Manufacturing Line

- RAW Material Sourcing for the 3 MW PV module manufacturing line

- Initial equipment set was geared to a 3MW output per year (3 shifts)

- Manufacturing Line Set-up, Equipment balancing

- Local Saudi team selection (Engineering, operator)

- Sourcing complementary expert team (Quality, maintenance)

- Build required Manufacturing team

- Development of training manuals and team training

- Development of manufacturing processes

- Manufacturing management

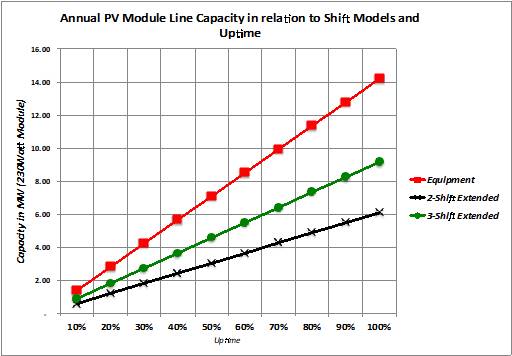

Upgrade to 12 MW PV Module Mfg Line

- Line balancing for 12 MW annual manufacturing output

- Selecting and replacing equipment to achieve target output

- Purchased and Installed the selected Equipment for output and higher level of automation

- Developed and implemented a challenging 3 shift operations team

- Hired and complemented existing team for 3 shift operation

- Developed and implemented ISO 9001:2008 Manufacturing processes to ensure product quality and reliability

- RAW Material Sourcing for the 12 MW PV Module Manufacturing Line

- Build required Manufacturing team

- Development of training manuals and team training for the 12 MW Line

- Developed and trained local Saudi management for this line

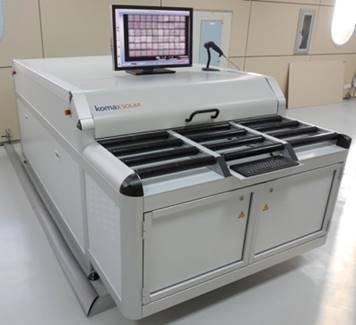

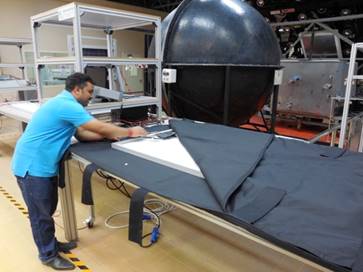

Development, Implementation and Accreditation of a ISO 17025

PV Laboratory

- Initial Set-up and lab equipment set was meant to test the output quality and reliability for the 12 MW Manufacturing output of PV Modules.

- In phase 1.1 the lab equipment set was extended to full capability of IEC61215 and IEC 61730 testing of PV modules.

- Assigned a team of technicians and engineers to run tests in accordance to the above IEC standards

- To be globally recognized, advised to go to full ISO 17025 accreditation for this lab

- Hired a specialized consultant for ISO 17025, IEC 61215 and IEC61730

- Developed Quality Manual, Management Procedures and Test Procedures as required by the standards

- Achieved first ISO 17025 Accreditation for the lab in February of 2015

- Developed and implemented marketing strategy for the lab

- Developed additional tests for harsh environments, as it suits the local environment, specified and sourced the required equipment for this test processes

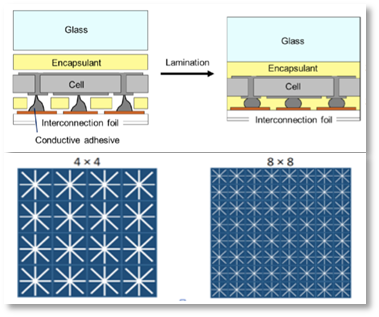

Development Line Back Contact PV Module

- Advised to search and evaluate alternative technologies for manufacturing c-Si PV modules for lower cost of ownership and higher performance

- KACST accepted to evaluate the Back Contact, one of the recommended technologies for this purpose

- Evaluated and sourced manufacturing equipment for a prototype line to build Back Contact PV modules

- Evaluated and sourced RAW material manufacturer for this process

- Produced PV modules with this technology for reliability and performance evaluation under harsh local conditions

- Established European R&D partner to further develop and test this technology

- Specified manufacturing process to integrate Back Contact c-Si Cell development and manufacturing into the 100MW Cell production line

- Assigned and trained specialized personnel to operate this Back Contact PV Module prototype line

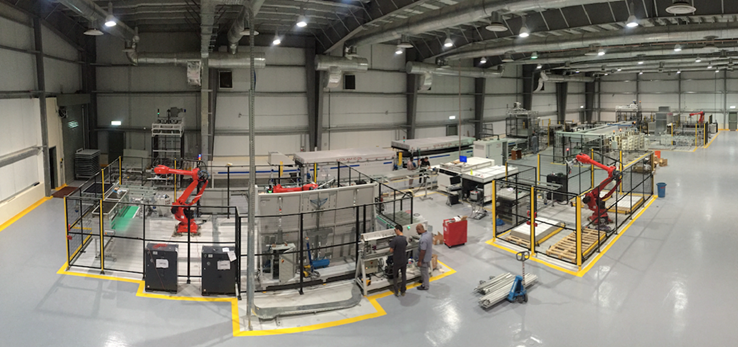

Development and Implementation of a 100MW PV Module Mfg Line

- Advised to enhance manufacturing capacity, as initial PV Solar projects in Saudi Arabia finally emerge and local capability and capacity should be established.

- Developed a feasibility study for size and efficiency, agreed finally with KACST management to go with a highly automated 100MW PV module manufacturing line.

- Provided line requirements to selected equipment vendors, established evaluation rules and recommended vendor of choice for automation level, capacity and budget

- Managed purchasing, shipping, installation and commissioning process.

- Selected and trained operators for 3 shift operation on this line (due to level of automation, operator staff same as in 12 MW line)

- Line currently is in final acceptance process, manufacturing ramp will follow

- ISO 9001:2014 is in process for this line

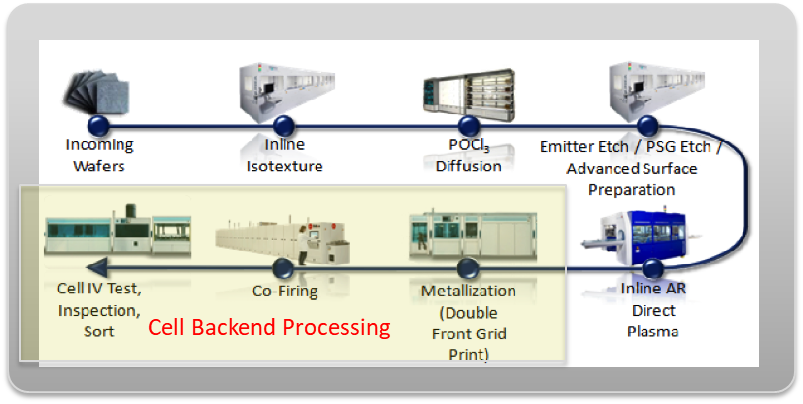

Development and Implementation of a 100 MW c-Si Cell Backend Mfg Line

- Advised to enhance depth in manufacturing capability, as initial PV Solar projects in Saudi Arabia finally emerge and local capability and capacity should be established. C-Si Cells are a critical component in the PV Module manufacturing process

- Developed a feasibility study for size and efficiency, agreed finally with KACST management to go with a highly automated 100MW c-Si Backend manufacturing line

- Provided line requirements to selected equipment vendors, established evaluation rules and recommended vendor of choice for automation level, capacity and budget

- Managed purchasing, shipping, installation and commissioning process.

- In process of hiring operator and process engineering staff

- Line currently is in final installation and commissioning process, manufacturing ramp will follow

- ISO 9001:2014 is in process for this line

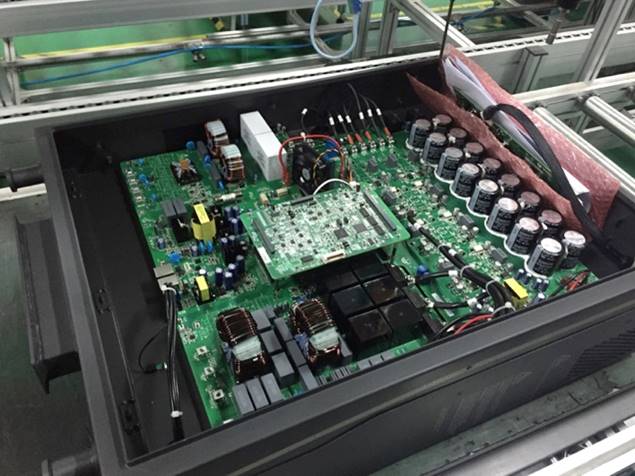

Development and Set-up of a 50 MW Inverter Mfg Line

- Advised to add Inverter manufacturing capability, to own a larger share in PV Power Plant technology and local content as initial PV Solar projects in Saudi Arabia finally emerge and local capability and capacity should be established.

- Developed a feasibility study for technology, size and project phases. Current level phase1, includes component assembly, testing and aging for 50 MW annual capacity

- Developed Partner in China to transfer technology and provide training to the local selected staff in Saudi Arabia.

- Managed purchasing, shipping, installation and commissioning process.

- Line currently is in final acceptance process for phase 1, manufacturing ramp will follow

- ISO 9001:2014 certification is in planning for this line for enhanced quality